Popular Models of Common Carbon Film Resistors

I. Introduction

Carbon film resistors are a fundamental component in electronic circuits, playing a crucial role in controlling current flow and voltage levels. These resistors are made by depositing a thin layer of carbon on a ceramic substrate, which allows for precise resistance values and stability. In this article, we will explore the characteristics, popular models, applications, and future trends of carbon film resistors, providing a comprehensive overview for engineers, hobbyists, and anyone interested in electronics.

II. Understanding Carbon Film Resistors

A. Composition and Structure

1. **Materials Used**: Carbon film resistors are primarily composed of a carbon layer, which is deposited onto a ceramic substrate. The carbon content can vary, affecting the resistor's overall resistance and performance. The ceramic substrate provides mechanical strength and thermal stability.

2. **Manufacturing Process**: The manufacturing process involves several steps, including the preparation of the substrate, the deposition of the carbon film, and the application of protective coatings. The carbon film is typically created using a process called pyrolysis, where organic materials are heated in the absence of oxygen, resulting in a conductive carbon layer.

B. Working Principle

1. **How Resistance is Created**: The resistance in carbon film resistors is determined by the thickness and length of the carbon film. By adjusting these parameters during manufacturing, manufacturers can create resistors with specific resistance values.

2. **Role of Carbon Film in Resistance**: The carbon film's resistive properties are influenced by its structure and composition. The arrangement of carbon atoms and the presence of impurities can affect the overall resistance, making it essential to control these factors during production.

III. Characteristics of Carbon Film Resistors

A. Resistance Range

Carbon film resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. This versatility makes them suitable for various applications, from low-power circuits to high-precision devices.

B. Tolerance Levels

Tolerance refers to the allowable deviation from the specified resistance value. Carbon film resistors generally have tolerances ranging from 1% to 5%, with higher precision models available for applications requiring tighter specifications.

C. Temperature Coefficient

The temperature coefficient indicates how much the resistance changes with temperature. Carbon film resistors typically have a temperature coefficient of around 100 to 200 ppm/°C, making them stable across a range of operating conditions.

D. Power Rating

Power rating is a critical characteristic that defines how much power a resistor can dissipate without overheating. Carbon film resistors are available in various power ratings, commonly ranging from 1/8 watt to 2 watts, depending on the application.

E. Noise Characteristics

Carbon film resistors are known for their low noise characteristics, making them suitable for audio and precision applications. The noise generated by these resistors is typically lower than that of other resistor types, such as carbon composition resistors.

IV. Popular Models of Carbon Film Resistors

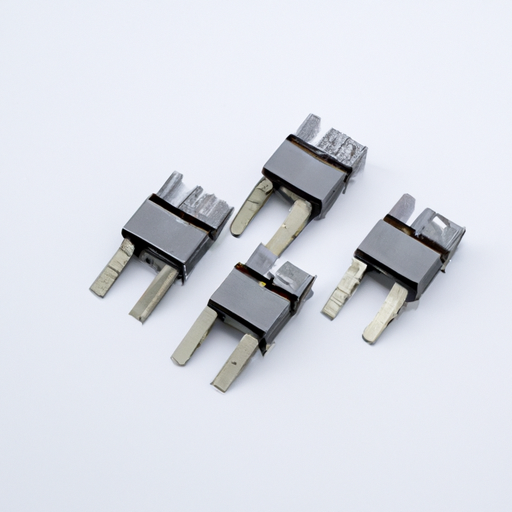

A. Overview of Common Models

Several models of carbon film resistors are widely used in the industry. Below are some popular models, along with their key specifications:

1. **Model 1: Yageo CFR Series**

- **Description**: The Yageo CFR series is a popular choice for general-purpose applications.

- **Key Specifications**: Resistance range from 1 ohm to 10 megaohms, tolerance of 1% or 5%, and power ratings from 1/8 watt to 1 watt.

2. **Model 2: Vishay MRS Series**

- **Description**: The Vishay MRS series is known for its high precision and stability.

- **Key Specifications**: Resistance range from 1 ohm to 10 megaohms, tolerance of 0.1% to 5%, and power ratings from 1/8 watt to 2 watts.

3. **Model 3: Panasonic ERJ Series**

- **Description**: The Panasonic ERJ series offers a compact design suitable for surface mount applications.

- **Key Specifications**: Resistance range from 1 ohm to 10 megaohms, tolerance of 1% or 5%, and power ratings from 1/8 watt to 1 watt.

B. Model Comparisons

When comparing these models, several performance metrics come into play, including stability, temperature coefficient, and noise characteristics.

1. **Performance Metrics**: The Vishay MRS series stands out for its low temperature coefficient and high precision, making it ideal for sensitive applications. In contrast, the Yageo CFR series offers a broader resistance range, making it versatile for various applications.

2. **Applications and Use Cases**: The Yageo CFR series is commonly used in consumer electronics, while the Vishay MRS series is preferred in industrial and automotive applications due to its reliability. The Panasonic ERJ series is favored in compact electronic devices due to its surface mount design.

V. Detailed Analysis of Selected Models

A. Model 1: Yageo CFR Series

1. **Specifications**: The Yageo CFR series features a resistance range from 1 ohm to 10 megaohms, with tolerances of 1% or 5%. It has a power rating of up to 1 watt.

2. **Advantages and Disadvantages**: Advantages include a wide resistance range and good stability. However, it may not be suitable for high-precision applications compared to other models.

3. **Typical Applications**: Commonly used in consumer electronics, such as televisions and audio equipment.

B. Model 2: Vishay MRS Series

1. **Specifications**: The Vishay MRS series offers a resistance range from 1 ohm to 10 megaohms, with tolerances as low as 0.1%. It can handle power ratings up to 2 watts.

2. **Advantages and Disadvantages**: Its high precision and low temperature coefficient are significant advantages. However, it may be more expensive than other models.

3. **Typical Applications**: Ideal for industrial equipment, automotive applications, and precision measurement devices.

C. Model 3: Panasonic ERJ Series

1. **Specifications**: The Panasonic ERJ series has a resistance range from 1 ohm to 10 megaohms, with tolerances of 1% or 5%. It is designed for surface mount applications with power ratings up to 1 watt.

2. **Advantages and Disadvantages**: The compact design is a significant advantage, making it suitable for space-constrained applications. However, it may not offer the same precision as the Vishay MRS series.

3. **Typical Applications**: Commonly used in smartphones, tablets, and other compact electronic devices.

VI. Applications of Carbon Film Resistors

Carbon film resistors find applications across various industries, including:

A. Consumer Electronics

In consumer electronics, carbon film resistors are used in devices such as televisions, audio equipment, and gaming consoles, where reliability and performance are essential.

B. Industrial Equipment

In industrial settings, these resistors are employed in control systems, automation equipment, and instrumentation, where precision and stability are critical.

C. Automotive Applications

Carbon film resistors are used in automotive electronics, including engine control units, sensors, and infotainment systems, where they help manage electrical signals and ensure proper functionality.

D. Telecommunications

In telecommunications, carbon film resistors are utilized in signal processing equipment, routers, and switches, where low noise and high reliability are paramount.

VII. Future Trends in Carbon Film Resistors

A. Innovations in Manufacturing

Advancements in manufacturing techniques are leading to the development of more precise and reliable carbon film resistors. Innovations such as automated production processes and improved materials are enhancing performance.

B. Emerging Applications

As technology evolves, new applications for carbon film resistors are emerging, particularly in the fields of renewable energy, electric vehicles, and IoT devices, where efficiency and miniaturization are crucial.

C. Environmental Considerations

With increasing awareness of environmental issues, manufacturers are focusing on sustainable practices, including the use of eco-friendly materials and processes in the production of carbon film resistors.

VIII. Conclusion

In summary, carbon film resistors are essential components in modern electronics, offering a balance of performance, reliability, and versatility. Understanding the characteristics and popular models of these resistors is crucial for selecting the right component for specific applications. As technology continues to advance, carbon film resistors will remain a vital part of electronic design, adapting to new challenges and opportunities in the ever-evolving landscape of electronics.

IX. References

1. Academic Journals on Electronics and Materials Science

2. Industry Publications on Resistor Technology

3. Manufacturer Specifications and Datasheets for Carbon Film Resistors

This comprehensive overview of carbon film resistors highlights their importance in electronic circuits, the characteristics of popular models, and their applications across various industries. By understanding these components, engineers and hobbyists can make informed decisions when designing and building electronic devices.